Meltshop

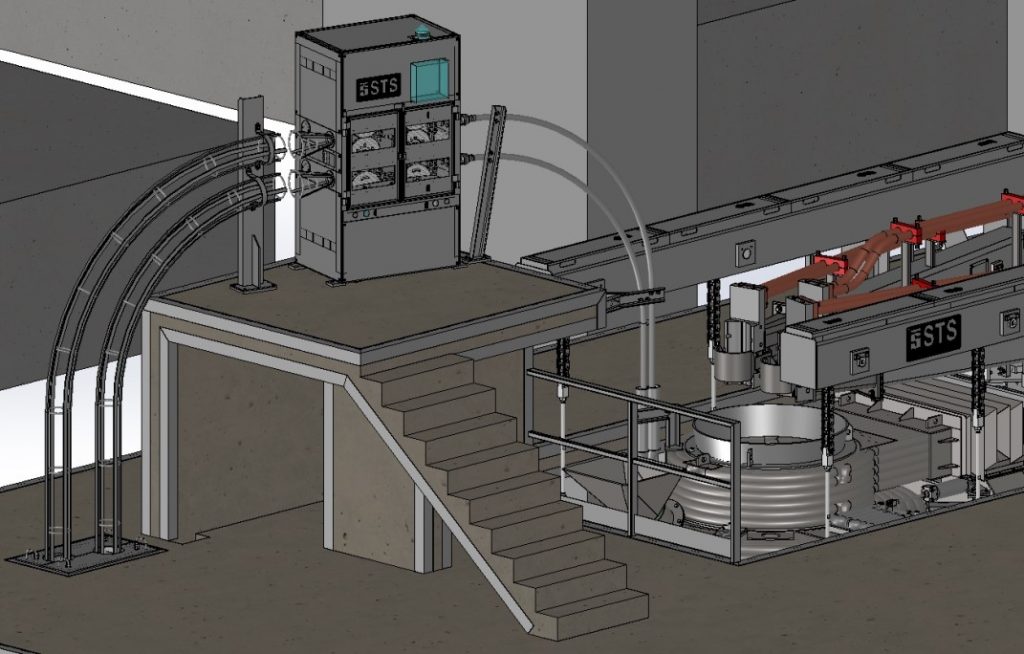

AUTOMATIC INERT GAS COUPLING

In the steelmaking process, the ladle is used to hold the liquid steel during refining, and the inert gas such as argon gas is blown from the bottom of the ladle.

Conventionally, the inert gas piping is mainly connected manually, but when the manual connection is made, the work efficiency is very low.

STS has developed a revolutionary low cost and high performance automatic inert gas coupling system for ladles.

With our affordable solution this technology is now made available also to small mills and is designed to be used either at the Ladle furnace or at the Vacuum degassing.

WIRE FEEDING MACHINE

The automatic Wire feeding machines have the function to inject cored or alloying wires in the bath of liquid steel at the EAF tapping position or at the Ladle Furnaces or at the Vacuum degassing stations.

Our wire feeding machines for EAF/LF/VD are the top for value for many and high efficiency.

The machine can be supplied with 2/4/6 feeding lines according to customer request.

Typical DATA

- Number of lines: n°2 or 4 or 6

- Injection speed: 40÷400m/min;

- Programmable length;

- Wire diameter:

- -Ø8÷16mm (cored wire),

- -max.Ø13mm (solid wire).