Automation

CCM- BILLET TRACKING

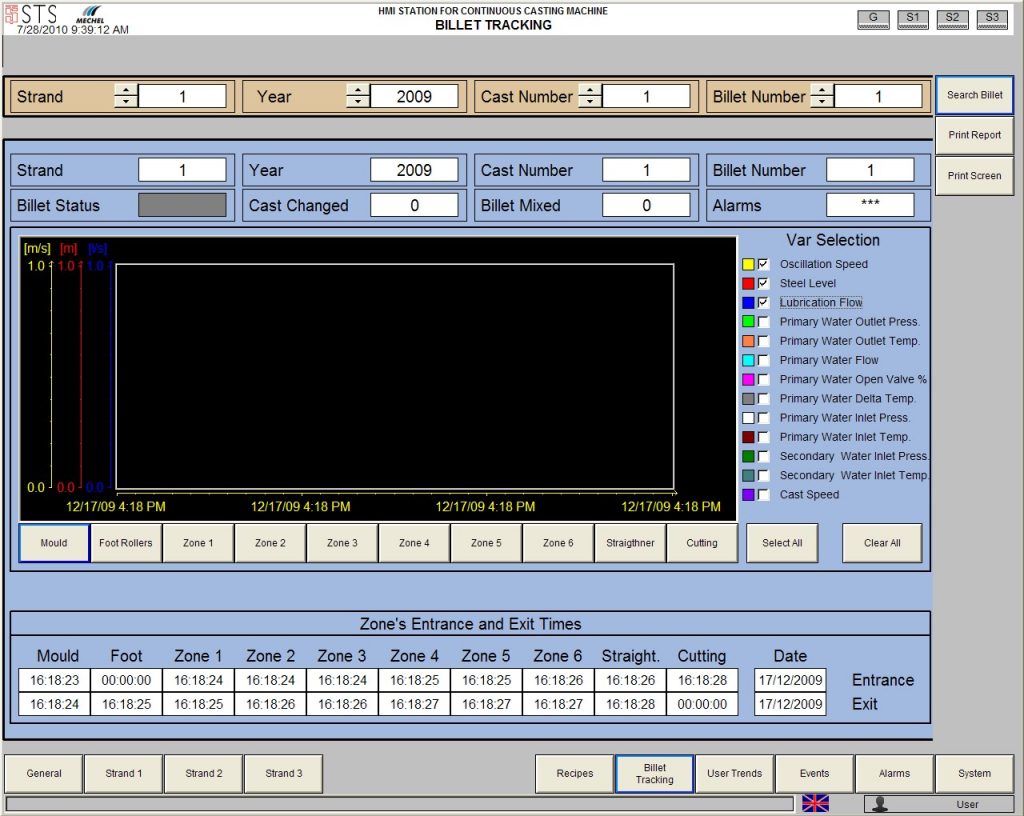

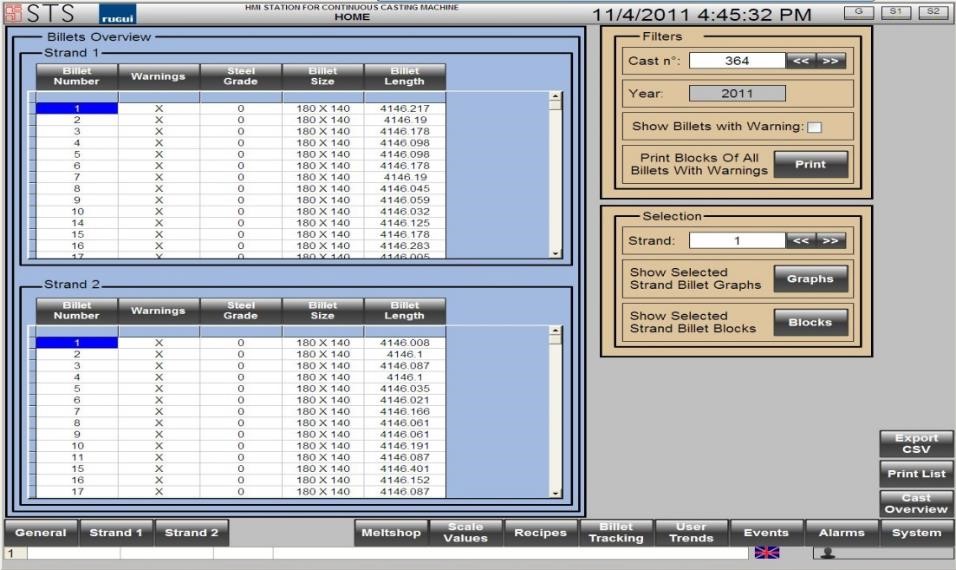

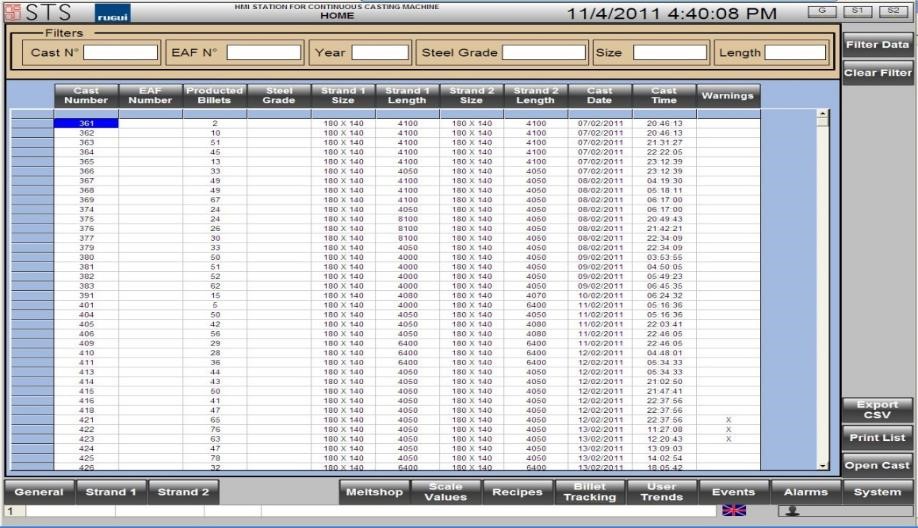

The software works dividing the cast sections in small slices and monitoring each slice during the complete billet formation. Whenever each slice passes through the cutting line it will become part of the next billet to be cut. This peculiar feature allows maintaining all information on each billet also when changing billet length. A database is updated with the data of all billets formed, allowing the operator to retrieve each single billet of each heat for offline analysis.

Billet Data will be stored for offline analysis and for automatic reporting of each cast with indicated average data and quality sensitive alarm logging of each produced billet.

The system is designed to monitor and record all the parameters that affect the quality of the billet:

- Casting speed

- Primary water parameters

- Sprays water parameters (each zone)

- Billet temperature (if temperature sensors are installed)

- Withdrawal rollers pressure

- Oscillation speed

The software is designed to be interfaced with billet marking machine

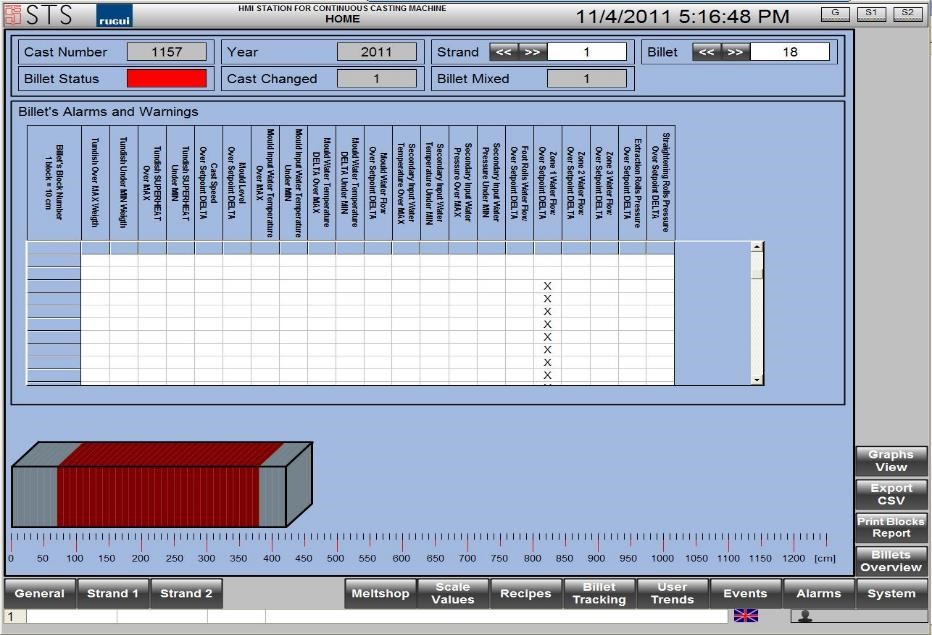

CCM- BILLET QUALITY CONTROL

In combination with our Billet tracking software STS Services supply a Billet Quality Control System.

For each billet all production critical parameters are monitored to control in case of discrepancies from set points.

In case of discrepancies the related billets can be tracked for further controls by technological specialists.

The system can be fully configurable by the production manager.