Caster

BILLET DEBURRING

Following market request STS has developed a new concept of Billet Deburring machine, having best performances and reduced maintenance.

STS solution is a mechanical device composed by a movable blade with specific design studied to remove the burr from the hot billet and fitted in the roller table after the torch.

According to hot sections and caster layout Single machine can be used for “cleaning” the cut either at the head and the tail of the hot billet.

BILLET MARKING MACHINE

The impact-marking machine is a useful system to identify each billet produced in order to assure production tracking that allows the finished product identification starting from the cast number.

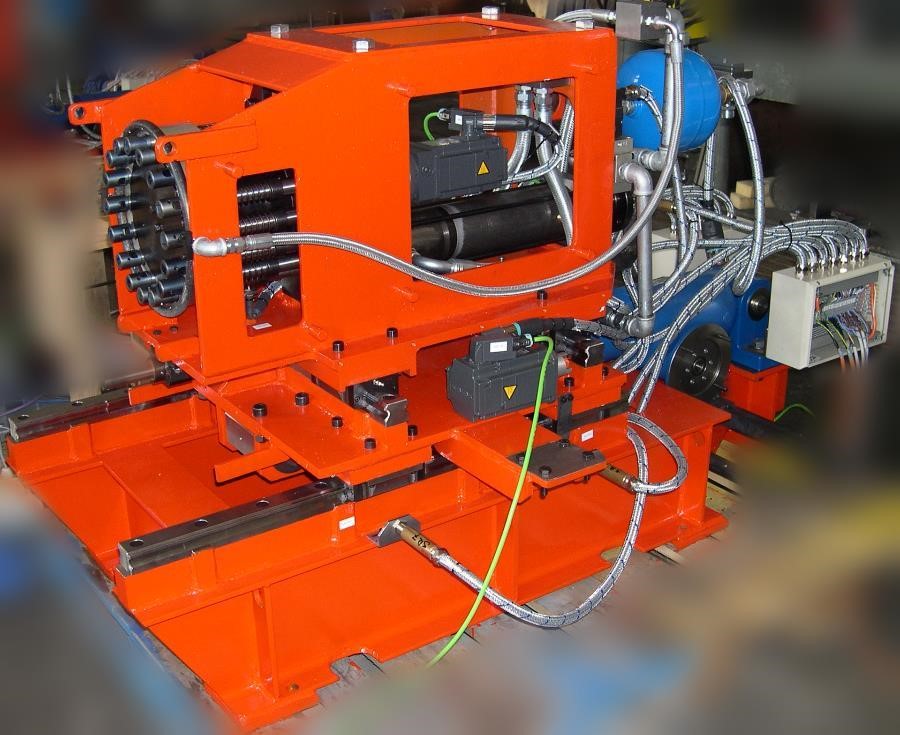

STS has designed its machine using the most heavy-duty components, in order to reduce human intervention to a minimum preventive maintenance, using a pneumatic system and electrical positioning actuators.

The standard machine has the disk capability of sixteen (16) characters with a dimension up to 6÷12mm and operates by pneumatic action on a hammer acting on a revolving head.

The characters are selected according to the input signal from the caster HMI so we can identify cast, strand and any requested data are normally maximum 11 digits. The selected operating range for this application is eight (11) characters of 10mm height and accordingly we have calculated the marking time of approximately 16/20 seconds.

According to peculiar layout and customer requirements the marking machine is normally installed on the roller table or on the first notch of the cooling bed