Special Systems

CCM Billet Tracking

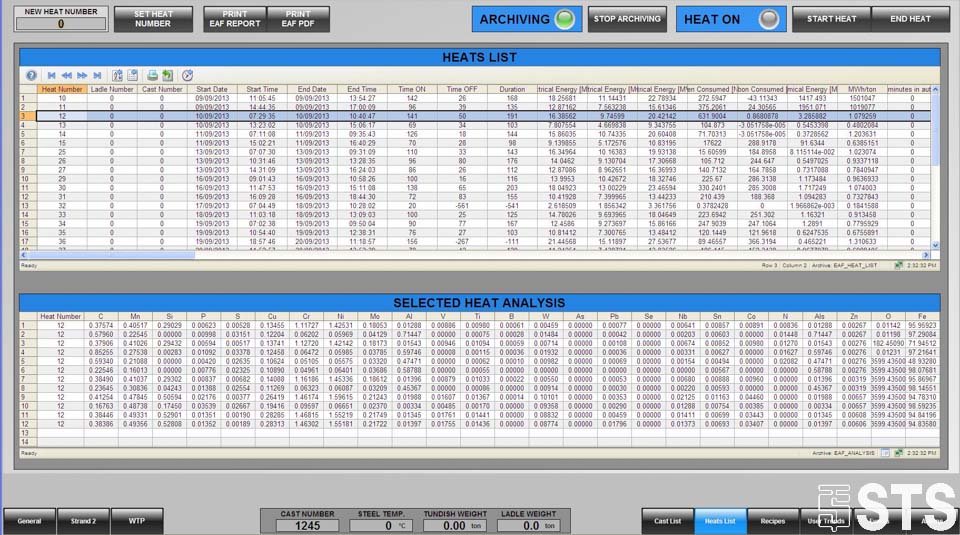

STS has developed a complete billet tracking system for Continuous casting machines. Each billet is divided in thin slices and each slice is monitored from its formation in the mold to the torch cut.

For each slice and for each billet all the process technological parameters are stored and made available to the operator for monitoring.

The system is capable to print for each single billet produced a production certificate. STS billet tracking system is designed work in combination with a Billet marking machine and with CCM billet quality control Software.

CCM Billet Quality control Software

In combination with our Billet tracking software STS Services supply a Billet Quality Control System.

For each billet all production critical parameters are monitored to control in case of discrepancies from set points.

In case of discrepancies the related billets can be tracked for further controls by technological specialists.

The system can be fully configurable by the production manager.

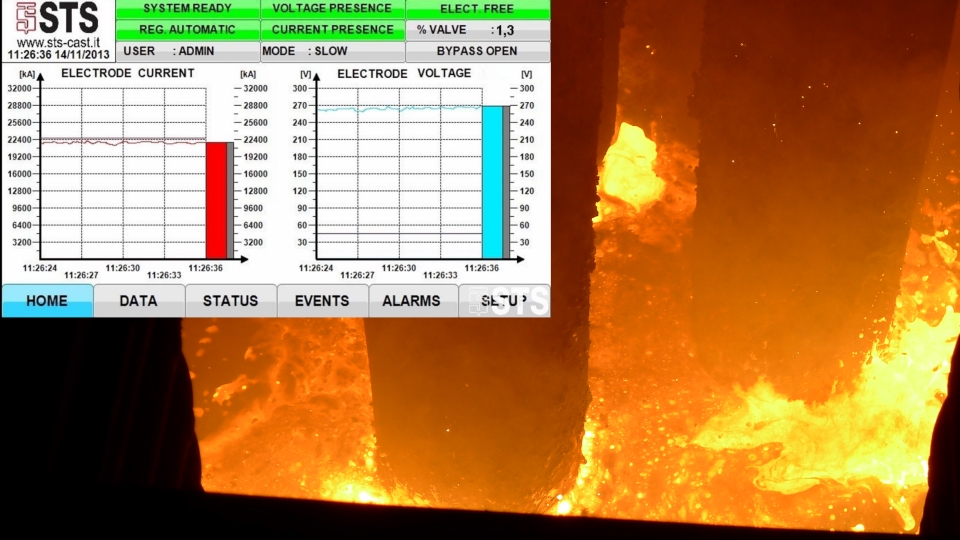

STS Automatic Furnace Electrode Controller

STS ELECTRIC CONTROL

STS provides a fully automatic, fully comprehensive solution for electrode control in three-phase electric arc and ladle furnaces. It regulates and dynamically adjusts the electric arc and makes the most efficient use of electrodes and electrical energy.

To reach this target a high speed electronic microprocessor board (PLC) has been develop. High processor speed and fast peripherals sampling speed gives the possibility to run complex algorithms and perform better regulation.

Such capabilities are absolutely necessary to reach the optimum working points and keep them during whole the melting process. This guarantees minimum consumption of electrodes, refractory, input power and reduces melting time.

STS Automatic Furnace Electrode Controller can be supplied either for new plants or as a revamping improvement to existing installations.

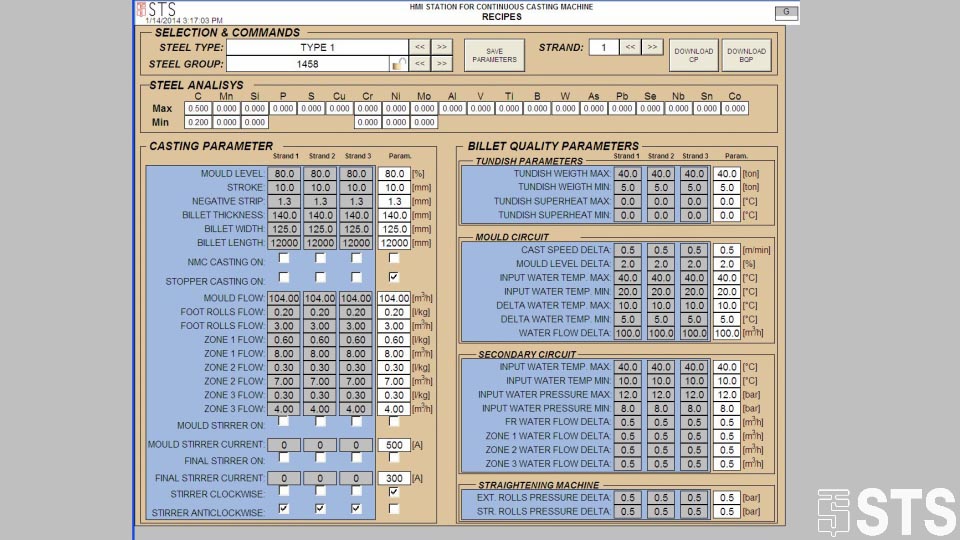

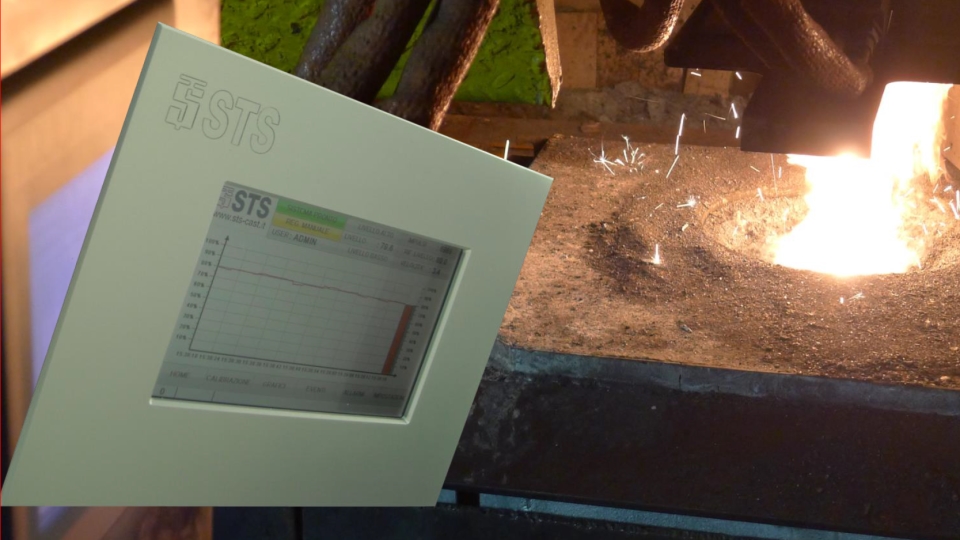

MOULD LEVEL CONTROL

STS has developed his own mold level measuring instrument especially developed for Continuous casting machines. The system is based on STS high speed electronic microprocessor board (PLC) and can ve connected to existing scintillation counters.